Case Study - Custom ERP for Manufacturing Company

The application effectively manages every stage of the technological process, from raw inputs to the production of the final product, ensuring complete coverage.

- Client

- Manager

- Year

- Service

- Web development, Cloud Services

Problems

to solve

Manager has been developed in order to solve a problem that may occur in companies whose main object of activity is production, namely the management of all entities of the company including customer orders.

Our client, private production company, reach out to us with the idea of building a custom ERP (Enterprise Resource Planning) that fulfills all the stages of a complete technological process, starting from the goods to the obtaining of the finished product, being covered all the stages of the technological process, following the delivery of the finished product to the end customer.

Solutions

The application fulfills all the stages of a complete technological process, starting from the goods to the obtaining of the finished product, being covered all the stages of the technological process, following the delivery of the finished product to the customer.

There have been over 3-months of close cooperation between the production company and XCODES team. We kicked off the project with a few day onboarding processes in their headquarters where we meet the team in person and learn the application’s specifics.

Based on application’s specifics, we started with the mockup & prototype over which we added the design. After everything has been defined and accepted, XCODES team started to build the application. The API was built in PHP with Laravel Framework, and the front-end in Vue.js with Vuesax Framework. DevOps processes have been implemented, like continuous integration and continuous deployment.

Technologies

- Vuesax

- Vue.js

- Laravel

- PHP

- Cloud Services

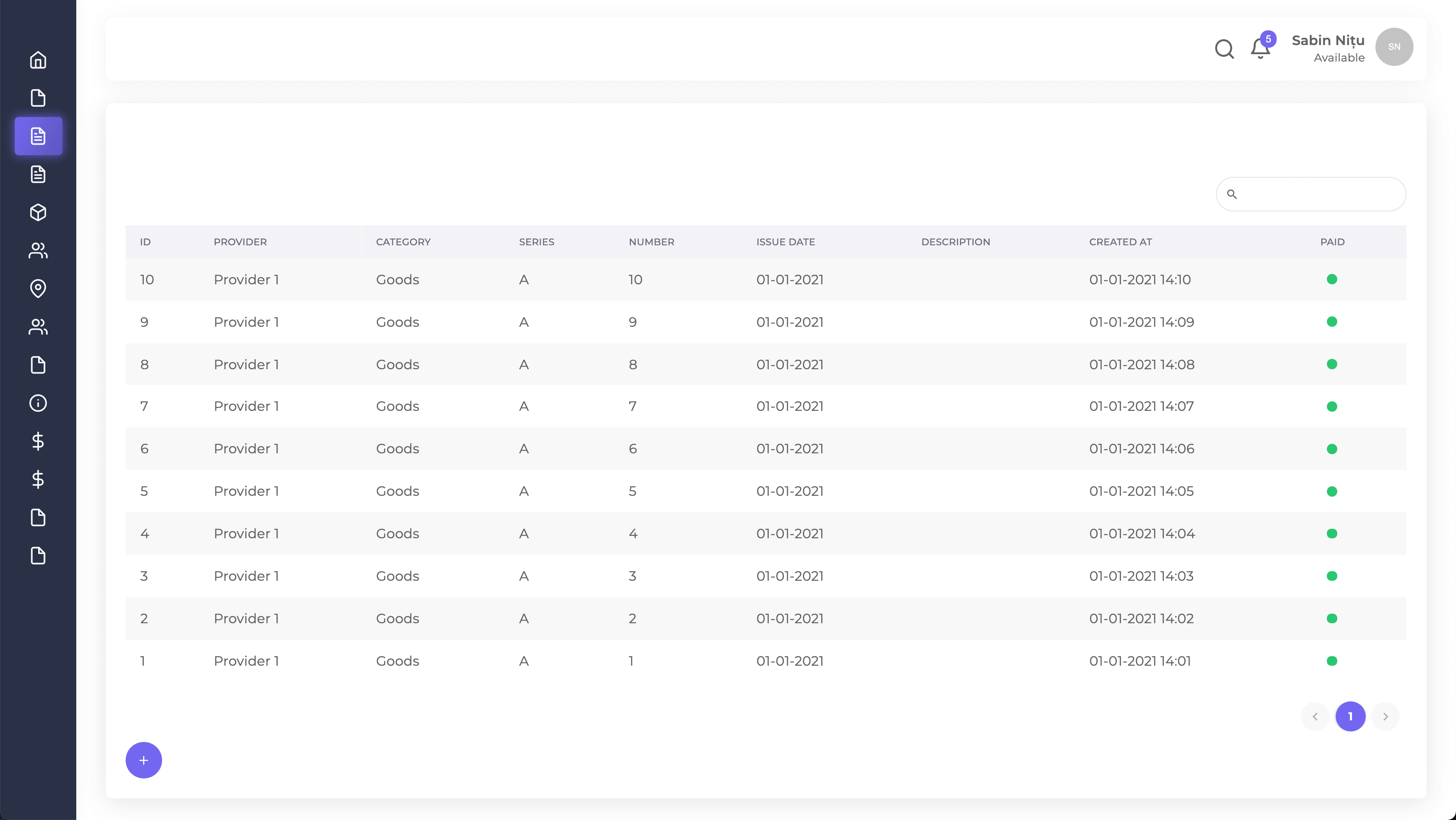

Invoices

The first step is to add invoices to the application. Once an invoice has been added to the application, the goods found on that invoice will automatically be visible on the goods page, and managed by the operator or administrator.

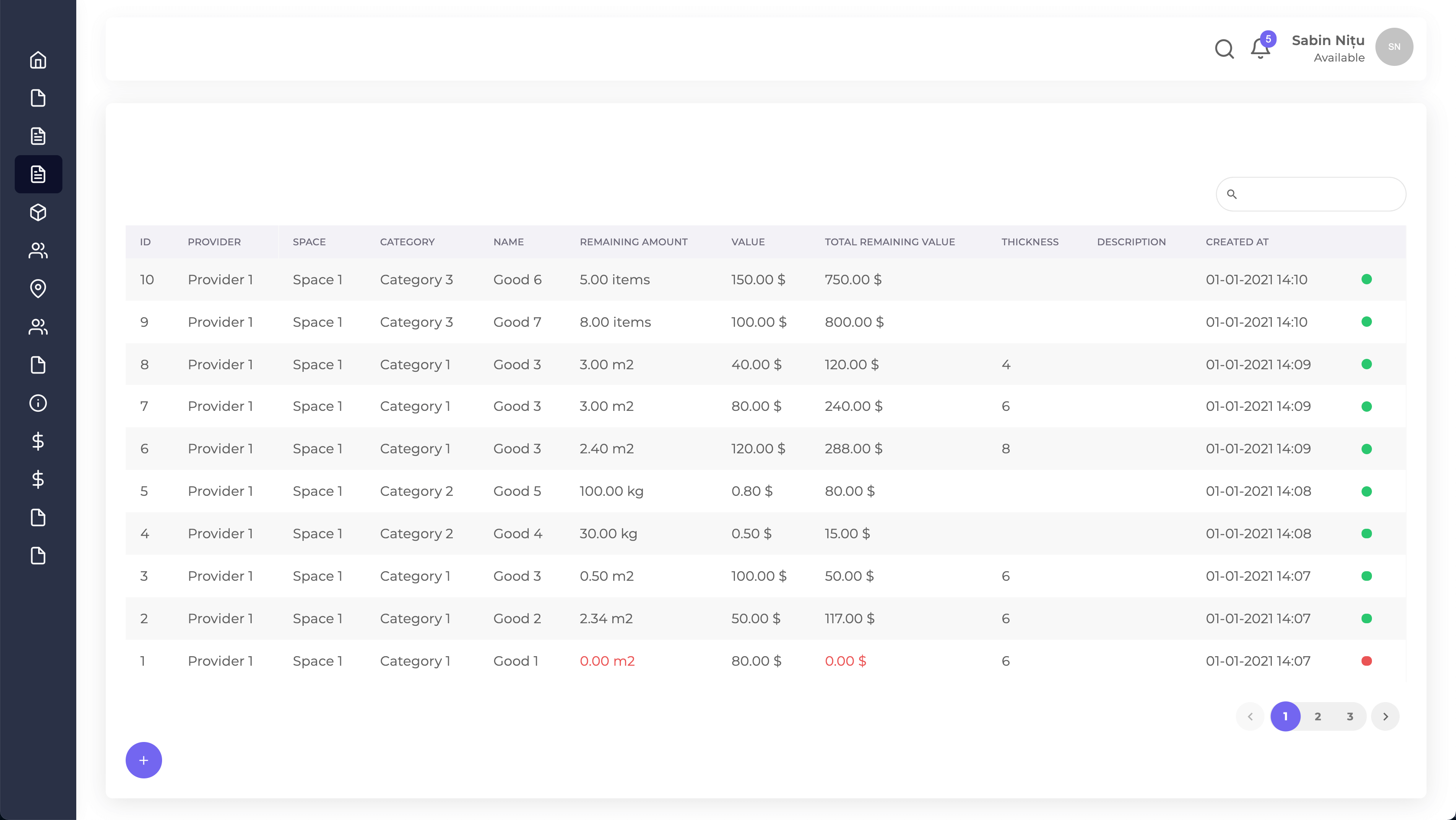

Goods

Goods are divided into three types: raw material, material and product. Depending on the unit of measurement, once the fields for length, width and quantity are populated, the quantity is calculated and populated automatically. After the good has been added, it is possible to access and use various actions such as: payment of the good, information and information about the employees, and the entry of the good in the technological process.

Technological process

Technological process includes all the processes and mechanisms used to transform raw materials, materials, products and semi-finished products into finished products, in order to satisfy customer needs.

Technological process is divided into three parts: productions, semi-finished products, finished products.

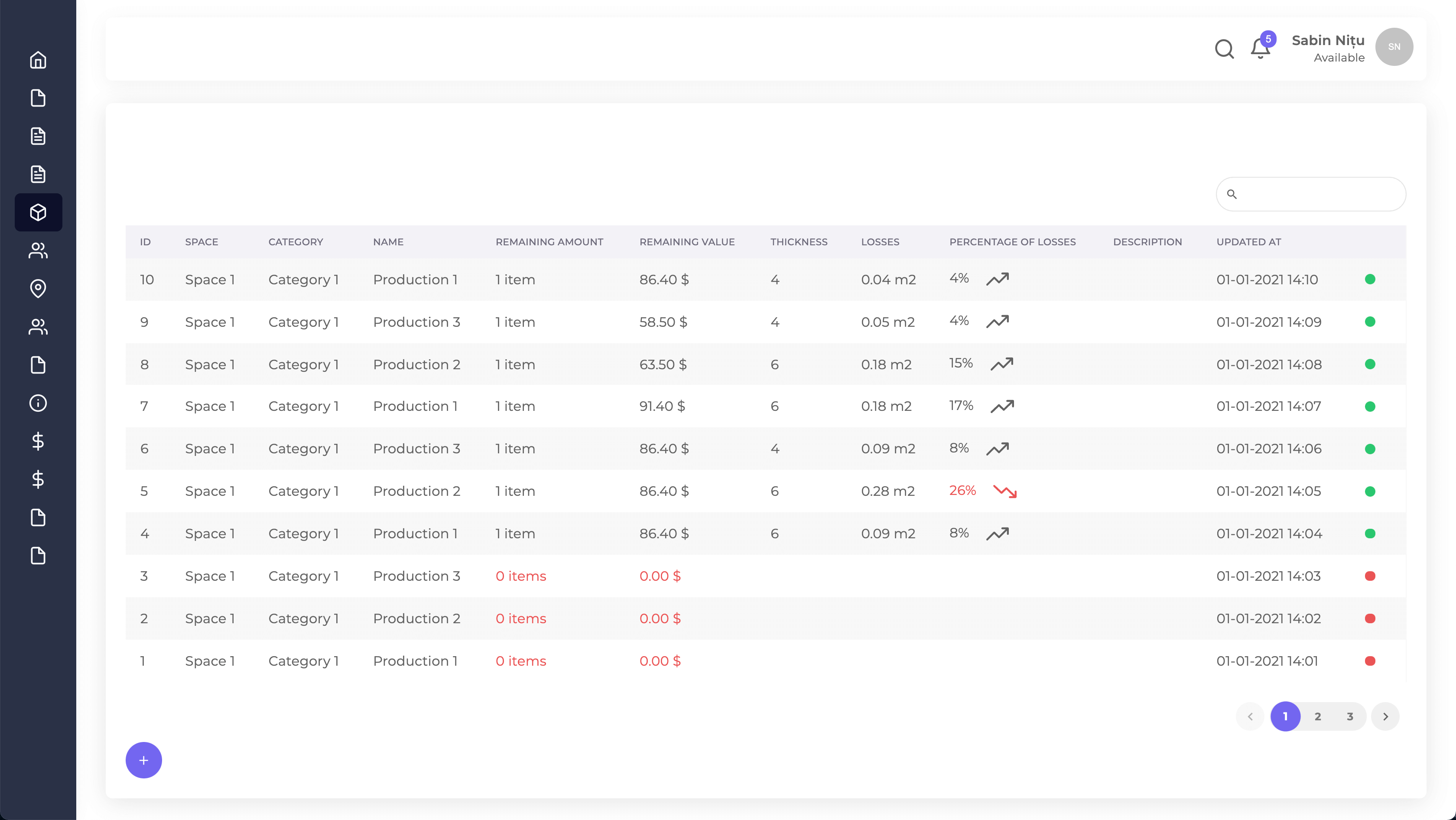

Productions

Production is the first step in the technological process. After the goods have been assigned to the production, the next step of the technological process can be passed, namely semi-finished products.

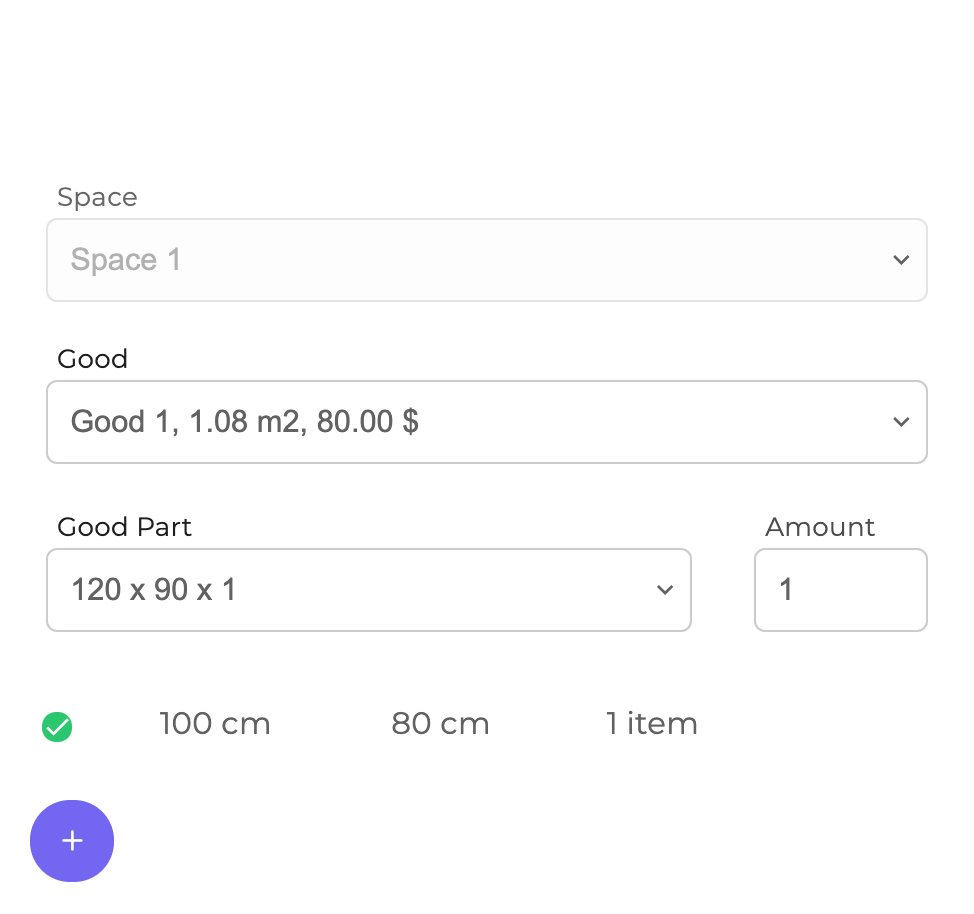

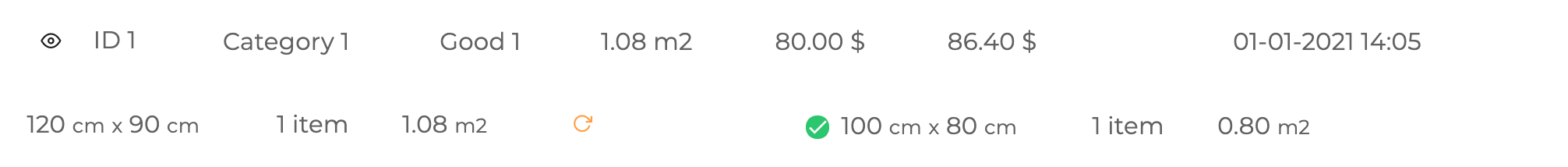

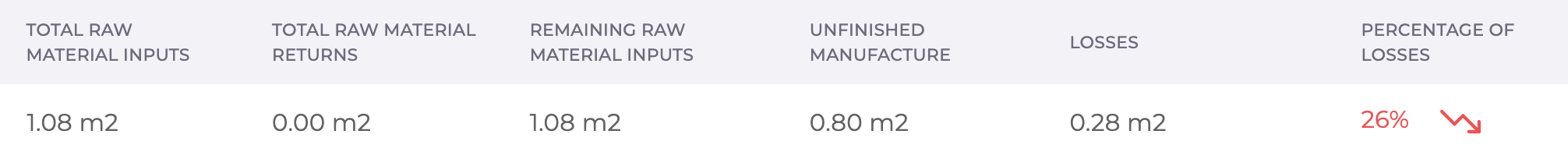

Production goods

After the production has been added, goods can be assigned. When assigning a good, the operator can select the “production part”, if it was added to the production creation. If the “production part” is selected, the loss of the good can be calculated based on specific formulas established by the company. After the good has been added, the loss can be seen and can be returned back to the goods. Through this process, that loss can be used in another production.

Semi-finished products

Semi-finished product is the product with a certain level of processing, which is delivered to another section or to another company to be further processed to obtain a finished product. The semi-finished product can remain in stock for a long time, unlike production. After the production has been changed into a semi-finished product can be accessed and use various actions such as: assigning a customer order, information and information about employees, or the change in finished product.

Finish products

Finished product is the product for which the processing has been completed, which has gone through all the steps of the technological process and which is used as such, without undergoing any further transformation, and can be stored to be delivered or shipped to customers.

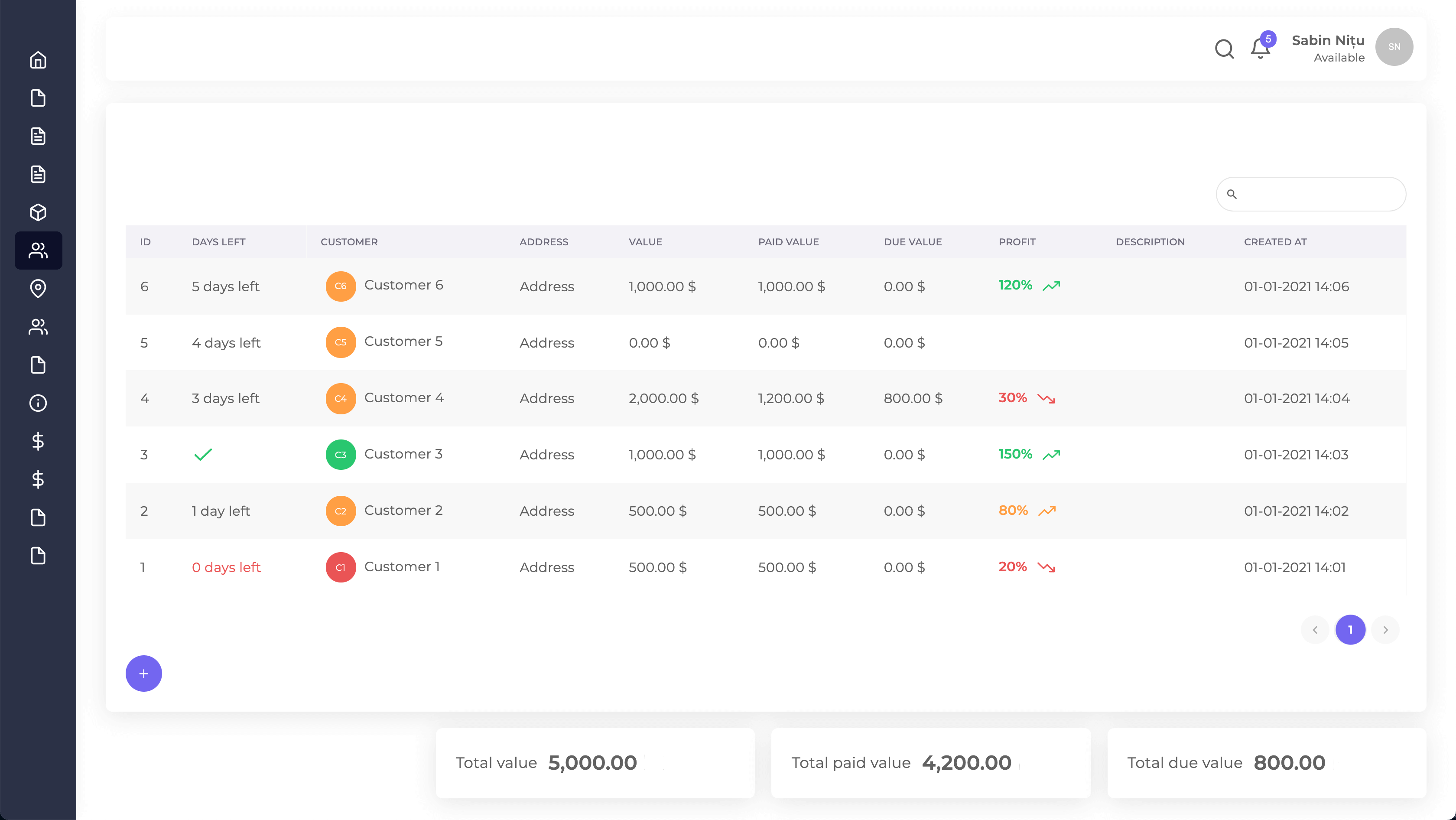

Customer Orders

The purpose of the company that use this application is to offer products or services to customers. Delivery can only take place if the total value of the client's production is paid. The addition of the total value of the work represents the sum of the estimate production established by the company and accepted by the customer.

Read review on ClutchThey managed to create the application according to our needs in a simple and easily accessible way.

Anonymous

CEO of Manager